TAKE 15% OFF YOUR ENTIRE ORDER BY MIDNIGHT TONIGHT - ENTER CODE NOW15 DURING CHECKOUT

February 04, 2014

Contrary to Western misconceptions during the 1930s and 1940s, the Japanese were ahead of many other nations within certain fields of innovation and technology. Some people are aware of the vastly superior Japanese oxygen 'long lance' torpedoes, superior optics, long ranging submarines, and the venerable Zero fighter that out-maneuvered everything in the sky in 1941. But few know about aotake. This strikingly bright coating was developed as a corrosion preventative in the early 1930s for use in the aeronautical industry, and it is technically one of a family of zabon enamel coatings. Surrounded by salt water and employing the world's largest aircraft carrier fleet, the Japanese were keenly aware of the importance of corrosion resistance. The Japanese also possessed a somewhat unique attitude with respect to the design and construction of their aircraft. Unlike other airplanes built for the air forces of other countries, Japanese aircraft were built to last. Disadvantaged as Japan was in terms of industrial output, the Japanese Army and Navy were expected to make do with the machines they were given for several years - as opposed to several months in the cases of other air forces. Japanese aircraft were built by hand, like Swiss watches. While these standards were compromised as greater demands were placed upon the industry after the Pacific War started in earnest, the application of the aotake primer coatings continued until almost the end of the war. Nothing preserved metal better in those days.

Aotake remains an unsung hero; superior to the American zinc chromate primers. Studies were conducted during and after the war in the United States that confirmed this, and aircraft archaeologists since the war have often remarked on the far greater longevity of Japanese aircraft abandoned in the jungles of the South Pacific. Charles Darby, the famous Australian wreck hunter, once said, "If you happened upon an aircraft in the bush that at once appeared amazingly intact, chances were that it was Japanese."

But it remains mysterious stuff. There are few examples of it still around to study. In spite of its longevity, 70 years or more has been long enough to virtually erase it from the remaining Pacific wrecks that remain unsalvaged. Most Japanese aircraft that were restored for museums and private collections after the war were stripped and rebuilt in such a way that this original material was destroyed in the process (ironically, some of these aircraft today are internally coated with something akin to the inferior zinc chromate). It's unfortunate, because few paints of wartime heritage could ever be described as genuinely 'pretty'. Aotake is an exception. In modern terms this coating might best be described as a candy coat. It was a translucent clear coating that was tinted in the interests of making it visible for uniform application. It possessed a high gloss, and due to its application over bright aluminum components it took on the appearance of a metallic-like bright blue or green that would look perfectly appropriate on the exterior of an American hot rod. Until the 1980s, aotake remained virtually unknown, like most details concerning Japanese WWII aircraft colors. But it is greatly misunderstood even today.

The coloring that was added to aotake did not have a specific standardized formula. Contrary to popular belief, while it could most often be described generally as 'blue/green' in appearance, it was very often more green than blue, more blue than green, yellow/green, and everything in between. Furthermore, all of these shades could be encountered within the framework of the same individual aircraft; often adjacent or overlapping each other. The reason for this is because aotake was applied to individual pieces - large and small, panels and braces - before they were assembled. They various components were coated by various subcontractors (the Japanese aviation industry was highly decentralized long before aerial bombing made it even more so), and even within subcontractors, different batches of aotake were of different shades. When these thousands of parts were assembled, the end result was very much a dazzling patchwork of bright colors.

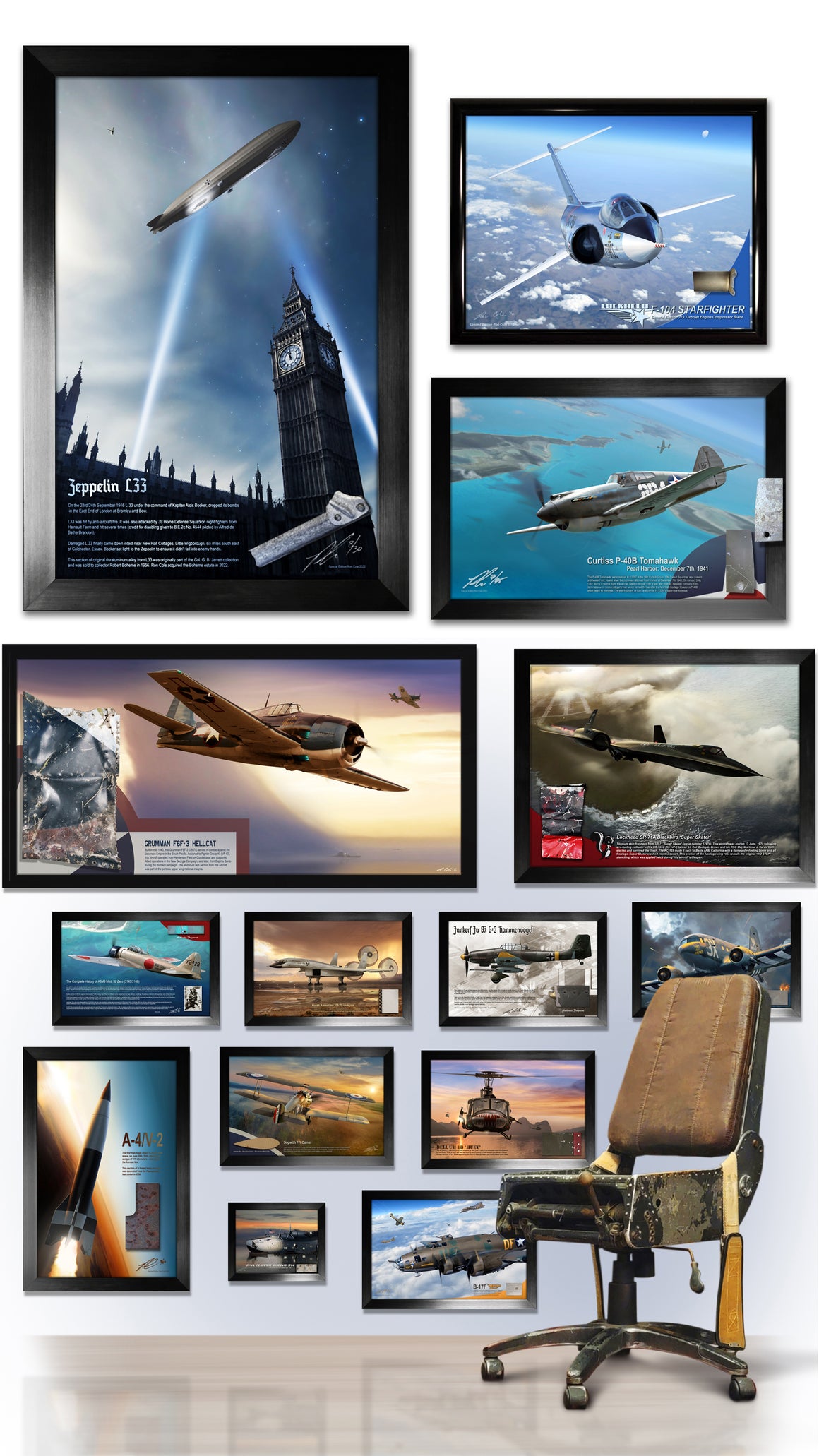

The following examples of applied aotake originated from the same aircraft - A6M3 Model 32 Zero, serial number 3148, built by Mitsubishi Heavy Industries in September 1942:

After an aircraft was constructed, including its exterior sheet aluminum, the Japanese commonly over-sprayed the bright aotake with dull black paint. But this was very much a hit and miss application. Obviously, much of the aircraft structure was difficult to access, and the black coating was very unevenly applied. When surviving examples of these parts are studied today, bright areas of aotake that were protected and covered by other components during construction can be seen adjacent to areas of dull black:

It has been suggested that the wide variations of color among aotake samples is due to fading; the theory that the coating changes hues upon prolonged exposure to sunlight, saltwater, and other factors. Isolating this particular study to the generally well preserved remains of this particular A6M3, which was located on a tropical island in the Marshalls between 1943 and 1988 with no care or cover - there is little evidence to support this. Among samples taken from throughout the aircraft, that were then completely disassembled to be used as templates for the manufacture of new parts, little evidence was found to support this theory. On the contrary, vastly different shades - ranging from bright yellow to green to deep blue - had been riveted together literally atop each other (see example in image two, above). Other areas of intact primer that revealed both exposed and previously covered aotake showed little or no difference between the two. But as with most of these debates, it's probably safe to say that nobody is absolutely wrong. Surely fading has played havoc in the cases of some paint samples - just not obviously so in the case of this A6M3, and fading cannot account for the wide range of shades revealed in this study.

The history and technical application of aotake might not be seen as especially critical archaeology, but when historians falsely attribute pieces of aircraft that were shot down over Pearl Harbor as originating from different machines due to different shades of aotake, for example, it's important to know the truth regarding the application of this material. It's also important for those intending to rebuild a Japanese aircraft that is potentially invaluable, and it certainly offers scale modelers with yet another tool in their arsenals to create a uniquely accurate model. Last but not least, we should give credit where credit is due: the Japanese got this one right!

- Ron Cole

Comments will be approved before showing up.

April 19, 2024

February 16, 2014

Join our mailing list and receive 20% off your first order!